Process technology

Neil A burns LLC is the north american marketing and sales arm of Ballestra and mazzoni technolgy for the production of surfactants, detergents and soaps.

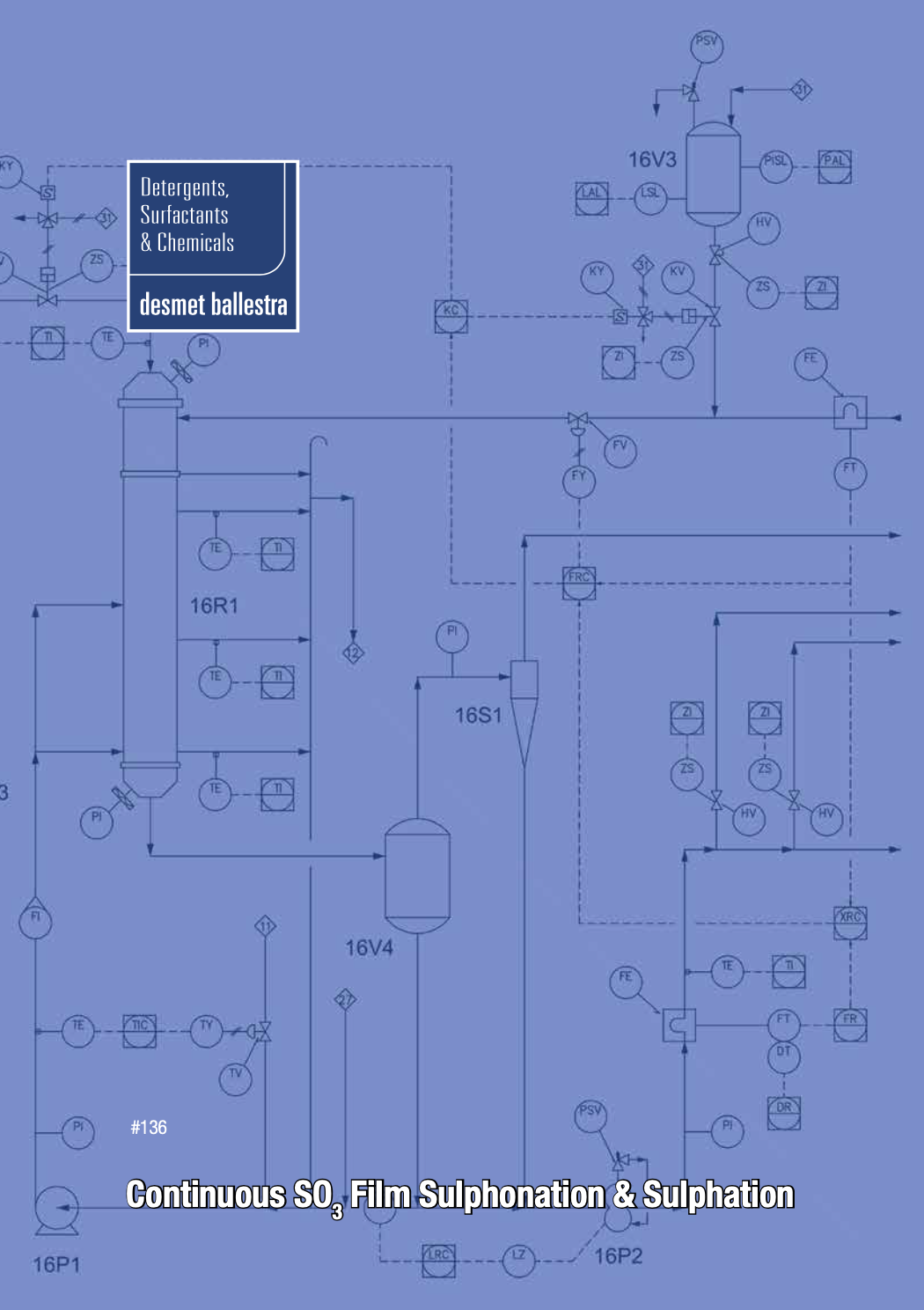

Sulfonation

Ballestra’s SULPHUREX film sulphonation technology presents outstanding advantages over the competing processes, namely:

Excellent performances in terms of product quality.

Exceptionally good conversion rate and colour with maximum achievable absorption of SO3 gas.

Simpler construction, which entails easier maintenance.

Lower operating pressurea and therefore cost.

No external cooling requirements and no need of chilling water equipment.

Extra low energy consumption.

Ballestra has implemented the world’s largest sulphonation plants (24,000 Kg/h as 100% active surfactant) and is constantly optimizing its process through the continuous work of its R&D Centre.

We are ahead of all dioxane standards and regulations pertaining to ether sulfates. Please see the download to the right and contact for a detailed discussion of options to keep your production assets ahead of regulatory developments.

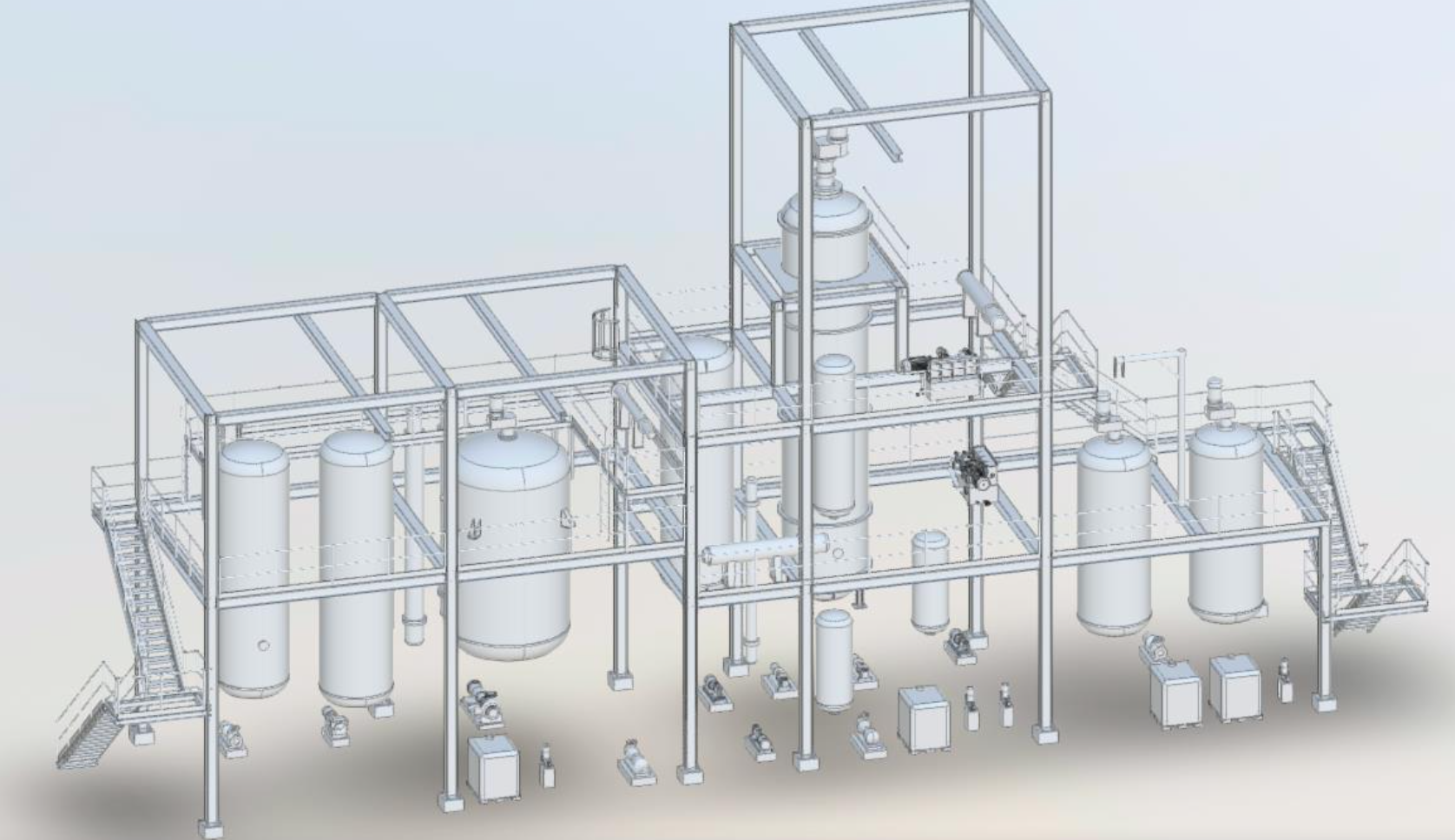

Alkoxylation

The “Enhanced Loop Reactor”, is the most advanced reaction system for alkoxylation processes. Thanks to the newly conceived double-acting gas-liquid mass transfer, the new “Enhanced Loop Reactor” features several outstanding advantages and better cost effectiveness with respect to the other technologies available on the market. The reactor is equipped with one or two external circulation loops (depending on production requirements), provided with heat exchangers for reaction heat removal and temperature control.

The circulation through the two loops can be started separately. One of these loops is designed to start-up batches with a small amount of chain starter, making it possible to attain a very high growth ratio (up to 1:80) in a single operation cycle. This allows to extend the production mix, avoiding dedicate intermediate storages, to improve the final product quality and to reduce production time of high molecular weight adducts.

Soap

Ballestra's head office for Soap activities is Mazzoni LB located in Busto Arsizio, Italy. Founded in 1946, Mazzoni LB is an engineering and manufacturing company, world leader in the design and supply of plants and machines for the production of soap and glycerine with a market share exceeding 60% and over 6,000 soap plants and machineries installed in more than 100 countries. Mazzoni LB technologies and services meet all the requirements of any toilet or laundry soap manufacturer, small or large, from oils & fats pre-treatment up to soap stamping.

Mazzoni LB is also a major world player in the chemical industry through its chemical department, specialized in the design and supply of complete plants for the production of rim blocks, household and personal care products, downstream oleochemicals and bleach water.

Specialty surfactants

Ballestra offers advanced manufacturing process technology for the production of:

APG’s - Alkyl Polyglucosides (download below)

Specialty Esters

Betaines / Amphoterics

Amine Oxides

Alkanolamides

These state-of-the-art designs backed by the technical expertise of Ballestra and highly engineered and efficient equipment are a highly cost effective option for companies to enter into the manufacturing of high value high growth specialties.

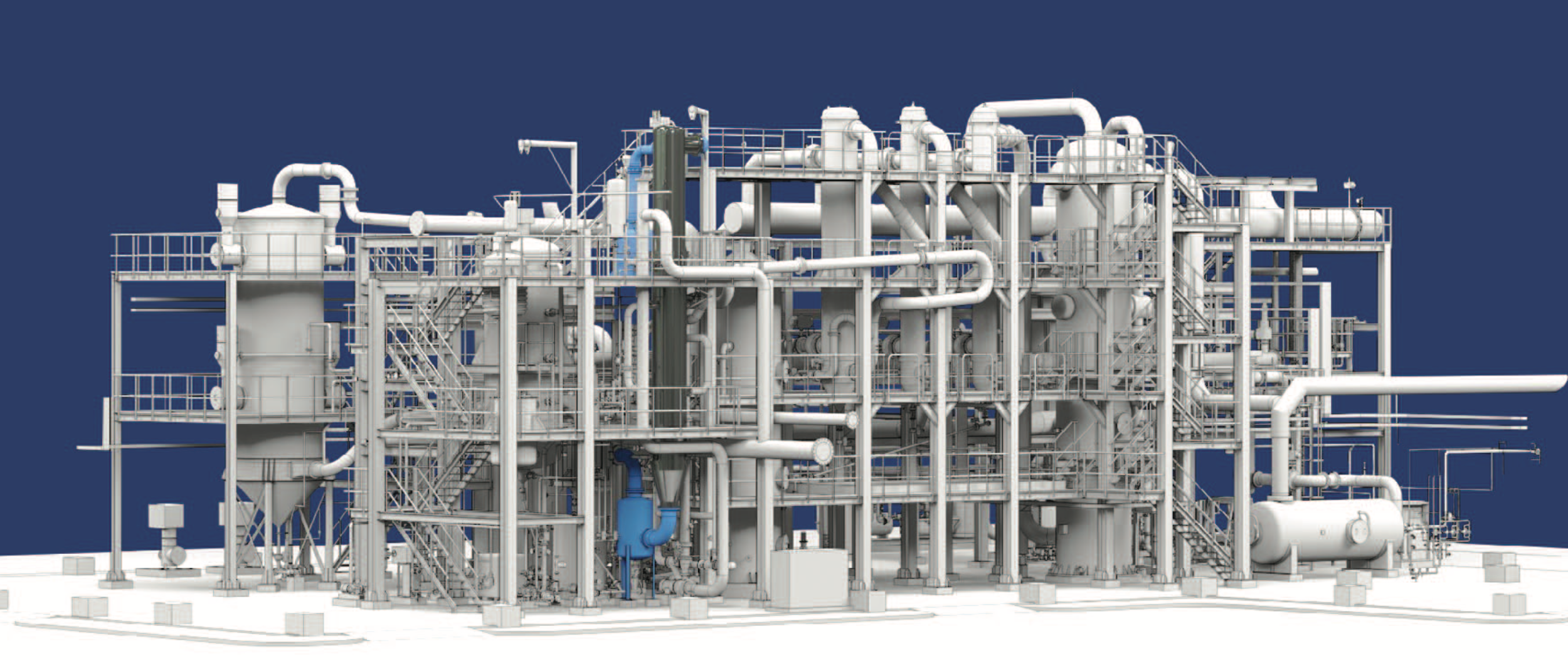

Detergents

Ballestra provides technology for the production of powder, “non-tower” and liquid detergents. The Ballestra technology for the production of detergent powder is installed in well over 550 plants globally. The innovative NTD - Non Tower Detergent production technology, based on the proprietary KETTEMIX reactor/granulator, has been developed by Ballestra to meet the worldwide market requirements for detergent powder production with reduced energy demand and manufacturing cost, without limitation to the physical, chemical and performance characteristics of the products. Ballestra also offers the compact, modular, highly automated DELIP process for the production of up to 100 MT per day of liquid detergent and personal care products.