Surfactants Monthly – September 2023

Surfactants Monthly Review

As regular readers know, we like to artfully weave into these blog postings, subtle promos for various business interests of the author. Most of the time, you hardly notice them. But I actually want you to notice this one. So here we are:

Shameless plug for the upcoming Surfactants Business Essentials Course (Virtual Version) produced and taught by me. In partnership, of course with the great I.C.I.S. The next 3-part course mini-series starts up Thanksgiving week (in the US); November 20 - 22 in the rest of the world. We hit Singapore at 6PM (local time), The UAE at 2PM, London at 10AM and for those really keen to pack in a full pre-Thanksgiving professional enrichment, New York at 5AM. If someone could join me in this pre-dawn classroom in the US Eastern timezone, I will buy you a coffee!

We go back to first principles - What is a hydrophobe? A hydrophile?.. and where do they come from? And we dig deep into the complex economic drivers in key supply chains like fatty alcohols and ethylene oxide. We talk about your favorite companies - customers, suppliers and maybe even your own employer. We've been running this course for over 10 years and we update it every single time. We have literally had successive generations of managers from companies attend. And, with every passing year, it seems like an increasing number of emails that I get, begin with “I took your course last year and….” That’s very cool, from my point of view.

The teacher: Me. Nothing is subcontracted to graduate students! The course is available live and exclusively on our proprietary online learning platform - fueled by the I.C.I.S. data powerhouse. Register here 🎓 ... Surfactants Business Essentials Course.

So – what else: As you probably gleaned from last month’s post, I am obsessed with AI – specifically in the field of AI/ML/SDL (Artificial Intelligence / Machine Learning / Self Driving Labs). So I think I’m going to write about it more in these blogs. Not about cool prompts and not about blog content creation; although for sure, I am fully expecting these posts to be largely written by AI with the next 18 months. The boring bits anyway. Witty aphorisms and charming references to 70’s Northern (English) arcana will be continue to be all mine. But that’s nothing unexpected. What I’d like to do here is to highlight one or two key breakthroughs in the AI/ML/SDL field and link them to the business of surfactants. So look out for that. They’ll be at the bottom, just ahead of the music section.

Another thing I’ve been thinking about a lot since last month is the How. In these blogs, we talk a lot about the what and the why (So and so built a new plant because they needed capacity in North America) but now much about How – that is How to be a better more effective manager. How to create a business where none existed before. How to fulfill your full potential. I see a gap. I think a lot about how to get the most out of the decreasing number of neurons in my brain but rarely if ever write about it. Is anyone interested? I’ve no idea but I’m going to take a tentative step into this area and perhaps by reader feedback you can let me know. This will be in its own clearly labelled section above the AI section.

And finally: Of course, our razor sharp observations on popular culture will continue to suffuse the blog for your entertainment and distraction. And so I have to address this Ancient Rome business. There’s some meme going round that talks about how many times a day a man thinks about ancient Rome. I had no idea this was also an American thing. But having grown up in a town (in England) that had a Roman fort and that was not that far from (Roman Emperor) Hadrian’s wall, thoughts of Rome were and are, never that far from the surface. The best roads up in that part of the world were laid on the routes taken by Roman roads and they were straight – joining A and B by a line with the shortest distance. The Romans did not screw around! Another thing; it was pretty clear how things went pretty quickly to hell in a handbasket when the Romans left. Buildings decayed. Roads fell into disrepair. Plumbing ceased to function. In short, Entropy did its inevitable thing without the Roman centurion to impose order. And that brings me to the another pop-culture question I’d like to introduce: How many times a day do you think about the second law of thermodynamics? For me – it’s a few times per day – sometimes on a weekend, occupying the whole day. Imagine my delight then, when I heard about the new book from the great Stephen Wolfram on the Second Law. I bought if of course. Apparently Wolfram has been thinking about the second law since he was 12 and now, 50 years later, he believes he understands it and so wants to share that understanding with the rest of the world. And I thought I was an Entropy nerd! I’ve started into it and it’s excellent. To put something together so rigorous and original, takes the discipline and perseverance of a Roman soldier. Well done Stephen.

Nice One Centurion!

Next up – The News – which is probably what you came for : This month, we’re starting with a long term view of prices in our field – and thereby, also providing a sneak peak into the sorts of trends we study in our Surfactant Business Essentials Course. Data provided as usual, courtesy of I.C.I.S.

Fatty Alcohols in South East Asia: (or Detergent Range Alcohols as they are more properly known). Prices for 1214 dropped at the end of September below $1,300 / MT, in line with decreasing palm kernel oil prices. Subdued demand for household and personal products didn't help either. According to ICIS reporting, over 300 KMT/ yr of capacity is offline for repair and or maintenance. Other plants are running at reduced rates. The following chart shows almost 20 years worth PKO and 1214 pricing FOB Southeast Asia – demonstrating the very close correlation.

Tight Correlation

In the US, 1214 pricing is similarly under downward pressure, due to weak demand and historically high inventories. Pricing is running at around $1,600 / MT , slightly more than half of pricing this time last year. In Europe, pricing also is moving down at around $1,400 / MT at end of the month. As we reported previously, Wilmar declared force majeure on fatty alcohols at Rozenburg, Rotterdam, the Netherlands, in July. The plant is rated at 120,000 MT/yr capacity. The force majeure remains in place and a restart is not expected until November at the earliest.

In the US market – the influence of petrochemical alcohols is particularly strong due to large capacity at Shell and Sasol. Therefore we keep a close eye on the relative price of PKO (the feedstock for oleo alcohols) and ethylene (the feedstock for petro alcohols). The following graph shows that despite a recent uptick in ethylene and the continuing downtrend in PKO, the so-called PKO premium over ethylene remains in positive territory, as it has for all of the last 9 years and much of the last 20 years.

Tight Correlation

In the US, 1214 pricing is similarly under downward pressure, due to weak demand and historically high inventories. Pricing is running at around $1,600 / MT , slightly more than half of pricing this time last year. In Europe, pricing also is moving down at around $1,400 / MT at end of the month. As we reported previously, Wilmar declared force majeure on fatty alcohols at Rozenburg, Rotterdam, the Netherlands, in July. The plant is rated at 120,000 MT/yr capacity. The force majeure remains in place and a restart is not expected until November at the earliest.

In the US market – the influence of petrochemical alcohols is particularly strong due to large capacity at Shell and Sasol. Therefore we keep a close eye on the relative price of PKO (the feedstock for oleo alcohols) and ethylene (the feedstock for petro alcohols). The following graph shows that despite a recent uptick in ethylene and the continuing downtrend in PKO, the so-called PKO premium over ethylene remains in positive territory, as it has for all of the last 9 years and much of the last 20 years.

As pricey as usual

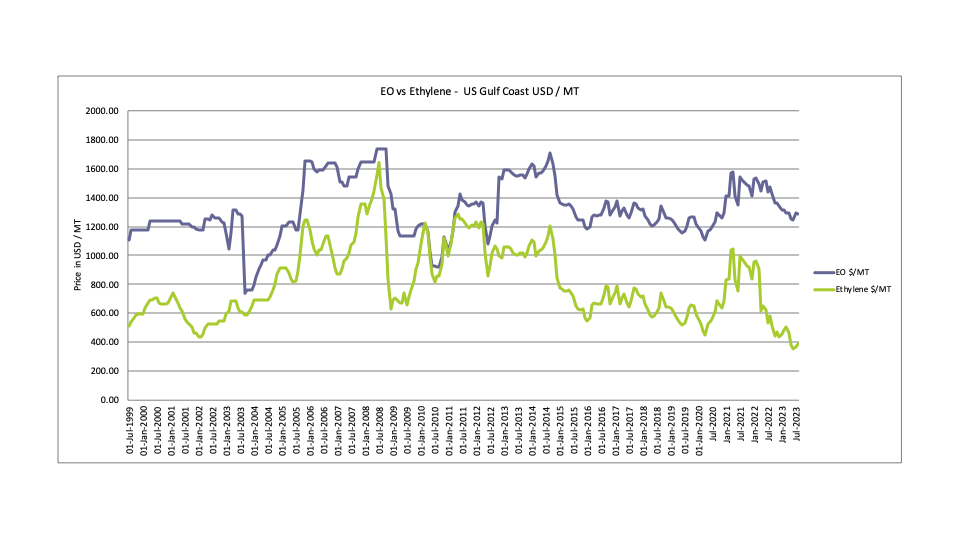

In the US, Ethylene Oxide prices settled down for August around $1,275 per MT (58 c/lb). This despite tight supply following the July Dow Plaquemine incident. That plant is expected to be out for another 6 months, according to ICIS reporting. Demand, meanwhile is weak in line with consumer demand in end use markets overall. The following graph illustrates the volatile relationship between ethylene and EO prices historically.

More correlated than not

In Europe, meanwhile, EO prices touched Euros 1,480 per MT in line with higher ethylene.

LAB and LAS prices have actually trended up recently in Asia. LAB settled around $1,450 /MT in SE Asia. Indian prices around $100 / MT more. Pushed up of course ultimately by upward pressure in the crude oil markets. LAS nudged up to around $1,250 / MT in SE Asia.

This graph shows the historically tight relationship between LAB and LAS pricing with the X representing the value in the equation LAS = LAB*0.75 = X (we explain a lot more in the course). For about the last year, X has been a bit tight historically, under $200 / MT as LAS manufacturers will no doubt attest.

Tough recent times for LAS makers

And if you needed any further reasons to keep an eye on crude here it is.

Convinced?

Continuing the news :

Coast Southwest: Big news published in the great HAPPI magazine. Coast Southwest acquired substantially all of the assets of the Paso Robles, CA, surfactant manufacturing facility from The Lubrizol Corporation. Currently, the plant manufactures surfactants used in a wide range of personal care and industrial products. A purchase price was not disclosed.

“This surfactant business is virtually in our DNA,” said Joseph C. Cimo, president of Coast Southwest. “I have had over a 30-year affiliation with this site under its present ownership and before that with prior owner Chemron Corporation. Acquiring Paso Robles is extremely complementary to our business strategy of geographic and functional expansion. We believe that Coast Southwest offers the best prospects for the long-term viability of the site, its employees and for the region economically.”

This acquisition follows the official opening of Coast Southwest’s new state-of-the-art corporate headquarters in Irving, TX.

“In a single month, we have completed the two most significant events in Coast Southwest’s 38-year history,” Cimo said. “Our third-generation business has grown from a regional chemical distributor with West Coast roots to a multi-location North American powerhouse. Our 105,660-square-foot headquarters becomes the center point of Coast Southwest’s strategy. The Paso Robles assets will allow Coast Southwest to improve its value chain position and assert its competitiveness in the marketplace."

Well, that is a big step in a good direction for Coast Southwest. From my recollection, the site is an excellent one and part of the machinery that propelled Chemron to a high quality / high service reputation in the surfactants industry. Best of luck to the new owners. !

Nice part of the world, Paso Robles. Google it.

Around the middle of the month ExxonMobil announced expanded chemical production at its Baytown, Texas (U.S.) manufacturing facility. The $2-B expansion is part of ExxonMobil’s long-term growth plans to deliver higher-value products from its U.S. Gulf Coast refining and chemical facilities.“With startup of these two new lines, ExxonMobil is delivering high-value materials for a variety of products that society depends on every day,” said Karen McKee, president of ExxonMobil Product Solutions. “We achieved excellent safety performance by leveraging our expertise to plan and execute large projects, while providing meaningful investment in the U.S. Gulf Coast.”

The new performance polymers line will produce 400,000 metric tons per year of Vistamaxx and Exact-branded polymer modifiers, which can enhance the performance of a broad range of chemical products used to make automotive parts, construction materials, hygiene and personal care products, and various packaging applications. Vistamaxx can increase the durability of consumer products like reusable containers to extend their useful life while also allowing for higher recycled content. Exact can help meet the growing demand in the auto industry for thinner, lighter weight parts that improve fuel efficiency.

Always loved this photo - Exxon Baytown

The new linear alpha olefins unit will produce 350,000 tons per year of Elevexx-branded products, marking ExxonMobil’s entry into the market. Linear alpha olefins are used in plastic packaging, high-performing engine and industrial oils and other applications. They’re also building blocks for surfactants, which reduce surface tension for cleaning and industrial uses, and drag reducing agents, which allow crude to flow through pipelines more efficiently. ExxonMobil maintained its investment in this project through the pandemic and related economic downturn. The company’s extensive project management experience and technology capabilities enabled the units to start up safely according to planned schedule. During construction, the project supported more than 3,500 jobs, and when fully operational, will directly employ 200 more people. ExxonMobil’s Baytown facility is one of the largest integrated and most technologically advanced refining and petrochemical complexes in the world. Founded in 1919, ExxonMobil’s Baytown area operations are located on approximately 3,400 acres along the Houston Ship Channel, about 25 miles east of Houston. They include a refinery, chemical plant, olefins plant, plastics plant and global technology center.

Interesting news from Lanzatech and Dow: LanzaTech Global, Inc. (NASDAQ: LNZA), the carbon recycling company transforming waste carbon into sustainable raw materials, has collaborated with Dow (NYSE: DOW) to introduce a new biodegradable surfactant to the home care market. Dow’s surfactant, EcoSense™ 2470, is made using LanzaTech’s CarbonSmart™ technology and ensures immediate market entry, while maintaining high-performance standards and advancing sustainability with recycled carbon materials. Surfactants are a critical ingredient for creating the foam and cleaning action of many household cleaning and laundry products.

LanzaTech’s biorecycling technology works like a brewery: proprietary bacteria consume carbon-rich pollution from industrial facilities, such as steelmaking plants, and convert it into CarbonSmart™ chemicals, such as ethanol. This ethanol can be converted into ethylene oxide, and subsequently used to produce surfactants.

This recycled carbon-based surfactant, marketed by Dow as EcoSense™ 2470, has versatile properties suitable for diverse home care applications. “The capacity to provide cleaning solutions made from recycled carbon with outstanding effectiveness is a distinguishing factor that significantly influences the purchasing decisions of household consumers,” said Farooq Alam, Global Strategic Marketing Director, Dow Home Care. “EcoSense™ 2470 underscores our dedication to eco-conscious surfactant manufacturing, serving as the gateway to a sustainable future. It sends a resounding message to both home care brand owners and consumers that sustainability and superior performance work hand-in-hand harmoniously.” “There is enough carbon above ground to make all the things we need,” said Jennifer Holmgren, CEO of LanzaTech. “We have been active in the ethoxylates space for several years, converting ethanol to surfactant ingredients, and with now Dow, our collaboration will enable us to greatly expand our reach in this market, which was valued at $19 billion in 2022. In this way, we can pave the way for recycled carbon home care products that deliver both sustainability and product quality. There is no need for compromise when doing good for the planet!”

The official launch of EcoSense™ 2470 will take place during a presentation at the Innovation Forum with Dow experts hosted during the SEPAWA ® Congress , held from October 26 – 28 in Berlin, Germany.

More big news from our good friends Ballestra (disclosure - the company has been a long-term client of mine). On Linkedin (only for now) they published the following: Introducing the NEW BALLESTRA R&D Pilot Plant renovated with the most updated TECHNOLOGIES to perform validation or product TEST on SULPHONATION/SULPHATION by SO3 (from 1 to 200 lt), Spray DRYING (up to 100 kg/h), PRILLING/COLD SPRAYING (up to 20 kg/h), GRANULATION continuous (up to 100 kg/h) and batch, Organic Chemical Synthesis (Esterification, Condensation, Quaternarization, Amidation, …), SAPONIFICATION, EXTRUSION, ETHOXYLATION-PROPOXYLATION (up to 150 lt/batch), Liquid & Powder Detergent and their intermediate manufacturing and much more …

BALLESTRA R&D works actively and closely with customers through joint development partnership programs based on strict confidentiality to develop new ideas, reliable processes, and products in demanded quality and yield, from initial laboratory study to pilot plant scale-up test until full industrial scale.

Everything you need to get into a grow a surfactants business

Finally – Why does this Indian lake foam so much? Is the delightful headline to an article in the Asian Scientist magazine. Apparently, Rains dissolve surfactants bound to lake sediments causing foaming in Bellandur lake in Bengaluru, Southern India. Hmm .. The lake has problems beyond surfactants. Bellandur Lake receives untreated sewage far beyond its capacity to break it down and has depleted oxygen that keeps surfactants in the system. In a vicious cycle, this problem has worsened over the years. Foaming has also been witnessed in other lakes in the city such as Varthur Lake. “We are planning sustainable water treatment strategies. The first step is to increase the oxygen levels in the lake. You can either add algae that can increase it or add treated water with higher dissolved oxygen” said Reshmi Das, the lead author of the lake study and a graduate researcher at IISc.

It happens, OK. I'm not going to gloss over it.

End of News: Start of the AI/ML/SDL Section

For the material here, I’m going to pull largely on publications connected to the University of Toronto’s Matter Lab, with which I have had the recent pleasure of collaborating.

This headline caught my attention: VirtualFlow 2.0 - The Next Generation Drug Discovery Platform Enabling Adaptive Screens of 69 Billion Molecules[1]. Here’s a portion of the abstract: Early-stage drug discovery has been limited by initial hit identification and lead optimization and their associated costs (1). Ultra-large virtual screens (ULVSs), which involve the virtual evaluation of massive numbers of molecules to engage a macromolec-ular target, have the ability to significantly alleviate these problems, as was recently demonstrated in multiple studies (2–7). Despite their potential, ULVSs have so far only explored a tiny fraction of the chemical space and of available docking programs. Here, we present VirtualFlow 2.0, the next generation of the first open-source drug discovery platform dedicated to ultra-large virtual screen ings. VirtualFlow 2.0 provides the REAL Space from Enamine containing 69 billion drug-like molecules in a "ready-to-dock" format, the largest library of its kind available to date. … We demonstrate a perfectly linear scaling behavior up to 5.6 million CPUs in the AWS Cloud, a new global record for parallel cloud computing. Due to its open-source nature and versatility, we expect that VirtualFlow 2.0 will play a key role in the future of early-stage drug discovery.

A key theme emerging from the recent AI workshop we held in Toronto related to end-to-end automation and co-ordination in a self-driving-lab environment. This paper introduces a formalized architecture for achieving this: ChemOS 2.0 an orchestration architecture for chemical self-driving labs.[2] The idea is in part explained in the abstract thus: “…. we introduce ChemOS 2.0, an orchestration architecture that efficiently coordinates communication, data exchange, and instruction management among modular laboratory components. By treating the laboratory as an "operating system" ChemOS 2.0 combines ab-initio calculations, experimental orchestration and statistical algorithms to guide closed-loop operations…”

A more practical paper is Digital pipette: Open hardware for liquid transfer in self-driving laboratories[3] . Here the authors note: “Although many pipettes are available for human scientists, robots cannot manipulate these pipettes due to the limitations of current robot gripper morphology. We propose an intuitive yet elegant design for a 3D-printed digital pipette designed for robots to carry out chemical experiments. Performance-evaluation experiments were carried out liquid transfer tasks. Our results show that robots with digital pipette could transfer liquids within 0.5% error. This error is comparable to the baseline set by commercially available human-handled pipettes.”

For those worried about the role of Humans in the brave new world of AI/ML/SDL, there is a paper published as a preprint this August- HypBO: Expert-Guided Chemist-in-the-Loop Bayesian Search for New Materials[4], which notes in part “Our proposed method, which we call HypBO, uses expert human hypotheses to generate an improved seed of samples. Unpromising seeds are automatically discounted, while promising seeds are used to augment the surrogate model data, thus achieving better-informed sampling. This process continues in a global versus local search fashion, organized in a bilevel optimization framework. We validate the performance of our method on a range of synthetic functions and demonstrate its practical utility on a real chemical design task where the use of expert hypotheses accelerates the search performance significantly.”

Humans in the decision-making loop. But for how long?

Tell me if these abstracts and links are helpful – or too academic. Let me know.

Next Section: The How. This month, I’d really like to get some feedback on what I’m thinking about our surfactant conferences going forward. No matter if you’ve been to scores of our events or are just considering your first one. I’d really like to get some input if you can spare a moment.

Our conference focus has been to tell the attendees what is going on in surfactants and advise them on whatto do about it. This has been very successful. However, we have rarely if ever touch on how to do it. The how involves things like communication, leadership, management, innovation, entrepreneurialism, motivation, networking – the many softer skills that business owners and managers need – whether in surfactants or anywhere else. Pretty much the only place these subjects have been addressed has been in my opening remarks at the beginning of each conference.

What I’m thinking about is to build in sessions or a separate module on the how subjects – with a surfactant flavor. My sense is that the space is fairly open. There are mega-stars of self-improvement like Tony Robbinsand Jocko Willink, but for a manager in surfactants area, who wants to learn what is going on and what to do and how to do it, where do they go? Maybe there’s an opportunity for our events to be the one-stop shop for the what and how of the business of surfactants? I’m open to ideas and thoughts. Everything is on the table, fitness, nutrition, creativity, productivity. Your feedback will guide the future of the events… and this blog.

Ready to fulfill your potential?

And finally – the music. I almost feel obliged to write about Taylor Swift because everyone else is. It occurs to me that I can not name or hum a single Swift song. I’m proud of that, although I suspect many blog readers are in the same boat. What does that say about our society, I wonder? Our divided polity, our fractured democracy, our salad-bowl not melting-pot? No idea and don't really care, you’ll be relieved to know. Ritchie Blackmore, though. Different story. He’s appeard in our blog countless times. His chords and solos have accompanied many great episodes in my personal life. I’ll go back to Deep Purple’s cover of Joe South’s Hush on their Shades album in 1968. Here’s a truly horrible video from what looks like the UK’s Top of the Pops from back then. Even then though you can feel the massive talent and fury lurking in Ritchies guitar.

Next up from the Book of Taliesyn, released a few months later, the instrumental, Wring that Neck. Only a band as huge as Deep Purple, could surely contain the talent and egos of Jon Lord and Ritchie. Note the foreshadowings of Highway Star and 16th Century Greensleeves buried in there … hear them?

I’ll skip the eponymous album and go to In Rock – the masterwork – the literal and figurative Mount Rushmore. And of course the gargantuan first song (long version) Speed King. Again the interplay of Lord and Blackmore – incredible..

Now let’s go to Machine Head because, well if you were alive in 1971, you know why. This album defined heavy rock. So the opening track is interesting to me. We’re going to listen to the live version of the aforementioned Highway Star. It suggests to me an unlikely delayed gratification, if you like, on the part of Blackmore, whose persona more usually matched that of petulant teenager than gracious world champion. Consider this. How does the opening track (as we pull it here ) from their first live album go with a keyboard solo first? Blackmore’s frustration is palpable as he finally gets to do this thing at 4:10.

Also on Machine Head, of course, Smoke on the Water. Here’s a cool vinyl version.

We’re not even done with this album yet. What about Space Truckin’?

Here’s two versions: first the original from the album

and now the truly monstrous (in a good way) live version from Made in Japan

OK – I could go on and take in all the later work with Rainbow and various solo efforts, but you can do your own research, I suppose. I just want to leave you with 16th Century Greensleeves by Rainbow. This live version exemplifies the contained rage of the Blackmore chord and solo. Nothing quite like it. And a hat-tip to RJ Dio who more than manages to keep up the intensity. I saw this performed live at Newcastle City Hall, 1979 the night before my Chemistry mock A-Level (google it). Still got an A. The peak of my chemicals career by far.

So, that’s it. I usually don't ask much of you in these blogs but this month, we’ve got 3 things for you to do.

Register for or forward info on the Surfactants Course

Give me some feedback on the AI/ML/SDL stuff above

Tell me what you think about the “How” idea above.

Thanks

Neil

[1] bioRxiv 2023.04.25.537981; doi: https://doi.org/10.1101/2023.04.25.537981

[2] Sim M, Ghazi Vakili M, Strieth-Kalthoff F, Hao H, Hickman R, Miret S, et al. ChemOS 2.0: an orchestration architecture for chemical self-driving laboratories. ChemRxiv. Cambridge: Cambridge Open Engage; 2023; This content is a preprint and has not been peer-reviewed.

[3] Yoshikawa N, Darvish K, Garg A, Aspuru-Guzik A. Digital pipette: Open hardware for liquid transfer in self-driving laboratories. ChemRxiv. Cambridge: Cambridge Open Engage; 2023; This content is a preprint and has not been peer-reviewed.

[4] https://doi.org/10.48550/arXiv.2308.11787