Surfactants Monthly - December 2023

December 2023 Surfactants Monthly

Happy New Year. Thanks to the many readers that provided a lot of great feedback on the blog format . One message, loud and clear. Get straight to the news. So here we go: The rest of the feedback is at the end, after the music and such.

The News

Early in the month, Holiferm made an encouraging announcement. In summary the company raised £18.5M ($23.7 M) to scale up to 15kta bio-surfactant capacity from Rhapsody Venture Partners and Clean Growth Fund. Here’s the whole Press Release:

Holiferm Limited, a spin out from the University of Manchester that manufactures sustainable biosurfactants has recently closed our Series B funding round. This has seen further funds invested by Rhapsody Venture Partners, a leading Boston based deeptech VC and Clean Growth Fund, a leading UK cleantech VC, both previous Series A investors.

The funds raised will allow the company to forge ahead with our scale up plans for our commercial plant. Holiferm’s Wallasey plant has a current capacity of 1.1 KTA. With this new investment new fermenters will be installed in the plant, increasing capacity to 3.5 KTA around the end of 2024, then further scaling up to 15kta capacity. This will enable full market launches by major multinational customers.

The funding will also significantly accelerate the works taking place at our bespoke research and development facility in Manchester. It will allow us to move forward with refining manufacturing methods for other biosurfactants and pushing these forward through pilot testing and commercial launch in 2024. The investment means we can also continue our ambitious hiring strategy to ensure we attract the best candidates from the UK and around the world as we apply the technology to a range of different chemistries and drive our products to net 0 scope 3.

Ben Dolman, CEO of Holiferm said, “This latest funding round highlights the scale of the opportunity with Holiferm’s technology, making the manufacture of chemicals cleaner and greener through the elimination of petrochemicals which is vital for not just the chemical industry, but the World as a whole. Both Rhapsody Venture Partners and Clean Growth Fund have proven exceptionally collaborative and supportive partners, and we are delighted that they are continuing with us on this journey and look forward to working together to transform the chemical industry.”

About Holiferm

Holiferm was founded on the back of patented fermentation with integrated gravity separation technology developed at the University of Manchester. As a company we aim to disrupt the market and replace all petrochemical produced surfactants with our naturally produced biosurfactants, thereby significantly lowering the amount of CO2 produced in chemical manufacturing. We use yeast derived from honey together with rapeseed oil and glucose to produce our biosurfactants. Our biosurfactants have applications in many products found around the home including cosmetics, skin care, shower gels and hand cleansers as well as in the agriculture and textile industries. Holiferm has a research and development facility in Manchester and a commercial plant in Wallasey. The plant currently produces 1.1 KTA, with plans to scale up significantly. We currently offer sophorolipids in both high and low foaming varieties, with other biosurfactants to be introduced to market in 2024.

BTW – I had the opportunity to tour the Holiferm site in Wallasey (near Liverpool) in early November. Very cool. I wish Ben the team much success. They’ll be presenting at our conference of course in May.

Not the only good things to come out of Liverpool

Opengate Capital sold Verdant to Korean company, Samyang in what looks to me like a textbook PE transaction. As reported in C&EN by Craig Bettenhausen, the price was $250M and Verdant’s estimated ’23 revenues are $210M. So, if we assume, say 15% EBITDA margin (Guessing. No inside knowledge), that’s $32M EBITDA and therefore a ~7.8X multiple. Again this is just based on a guess of a 15% EBITDA margin. If the margin were higher the implied multiple would be lower. In any event – a textbook deal. Verdant got going in 2021 when Opengate bought Solvay’s amphoterics business (the old McIntyre mainly) with sites in University Park, IL, Halifax, UK and Genthin, Germany. There were some small add-ons, including Baze and Deforest and then a sale in about 2.5 years. That’s the way to do it and John Foley’s (retiring CEO and friend of the blog) gotta be quite pleased as does the Opengate team. Who is Samyang? No idea until now. They are 100 year (in 2024) old Korean company. According to their website, they are in chemicals, food, biopharmaceuticals, packaging and some other businesses, including cosmetics. The chemicals piece, prior to Verdant, includes plastics, resins and a few other odds and ends. Until now, they have not had a significant physical presence in the US. They own KCI, cosmetics ingredients, which seems like a decent fit with Verdant. BTW – another friend of the blog, Todd Nelmark, will run the new Samyang subsidiary going forward. Welcome to our surfactant industry, Samyang! It’s not even 2024 yet and it has started. Watch out for more Asian acquisitions in this value chain in the US.

More M&A in 2024

What else .. well, as we reported back in June, Solvay is splitting itself into 2 companies, focused on specialties and commodities, respectively. Earlier in December, the company reported that the separation is now done. Solvay has spun off its specialties segment which will now be called Syensqo. [How do you pronounce that? I’ve no idea. Hopefully I’ll find out in Orlando later this month] According to the announcement, Solvay will comprise the mono-technology businesses including soda ash, peroxides, silica, solvents and rare earths. Syensqo will cover specialty polymers, composites, surfactants, aroma, technology solutions, and oil and gas, as well as the four growth platforms in batteries, green hydrogen, thermoplastic composites and renewable materials, and biotechnology. Syensqo’s listing on Euronext Brussels and Euronext Paris, under the ticker SYENS, began at market opening on Monday 11 December. Interesting. I asked GPT-4 what he thought of this split and the impact for shareholders. This is what he said. :

The split of Solvay into two independent companies, Solvay and Syensqo, was a strategic move to create value for shareholders by focusing on their respective core businesses. Solvay retained its essential chemicals portfolio, while Syensqo became a science company of explorers, offering specialty materials and solutions1 2.

The market reaction to the split was positive, as both companies saw their share prices and market capitalizations increase after the separation. Syensqo started trading at €90 per share on December 11, 2023, resulting in a market capitalization of €9.5 billion9. By December 15, 2023, its share price rose to €94.50, and its market capitalization reached €9.98 billion6, implying a 5% increase in value. Solvay, on the other hand, closed at €26.24 per share on December 14, 2023, with a market capitalization of €2.72 billion11. On December 15, 2023, its share price increased to €26.65, and its market capitalization rose to €2.76 billion11, indicating a 1.5% increase in value.

Therefore, based on the share price and market cap data, the split has been a success for shareholders, as both Solvay and Syensqo have gained value and recognition in the market. The split has also enabled the two companies to pursue their own growth strategies and innovation agendas, which could further enhance their competitive advantages and profitability in the long term.

Source(s)

1. Solvay marks new era after successful Syensqo spin-off

2. SOLVAY and SYENSQO revealed as new company names

3. Syensqo lists on Euronext Brussels | euronext.com

4. SYENS | Syensqo S.A./N.V. Stock Price & News - WSJ

5. Solvay SA (SOLB.BR) Stock Price, News, Quote & History - Yahoo Finance

6. Solvay to become Solvay and Syensqo after 2023 separation - CEO

7. Solvay's plastics business will be part of new firm Syensqo ...

8. Solvay announces the publication of a supplement to its information ...

9. Syensqo SA (SYENS) Stock Price & News - Google Finance

10. Syensqo : share price rises sharply on its stock market debut

11. Syensqo successfully launched on Euronext - GlobeNewswire

12. Solvay SA (SOLB) Stock Price & News - Google Finance

13. Solvay (SOLB.VI) - Market capitalization - CompaniesMarketCap.com

14. Solvay (SLVYY) Stock Price, News & Analysis - MarketBeat

15. Solvay stock, shares & ADRs | Solvay

Ok then. There you are.

Yeah - I know I said it was a “he” in the text. Still haven’t decided..

A little bit of M&A that almost went by unnoticed but for the efforts of the great Al Greenwood of ICIS. On Monday, December 11, Innospec completed the acquisition of QGP Quimica Geral. Innospec did not disclose financial terms. QGP was founded in 1992 under the name Tanquimica. With the acquisition, Innospec said it now has a meaningful manufacturing and product-development base in South America. The acquisition also provides Innospec with new chemistries in surfactants and other products. Innospec will integrate QGP into its Performance Chemicals business. According the GPT-4, Tanquimica is a Brazilian company that produces and distributes chemical products for various sectors, such as agriculture, cosmetics, food, mining, and textiles. Some of their main products are surfactants, emulsifiers, dispersants, solvents, and biocides. It imagines their operations as follows.

I suspect they’re not that big

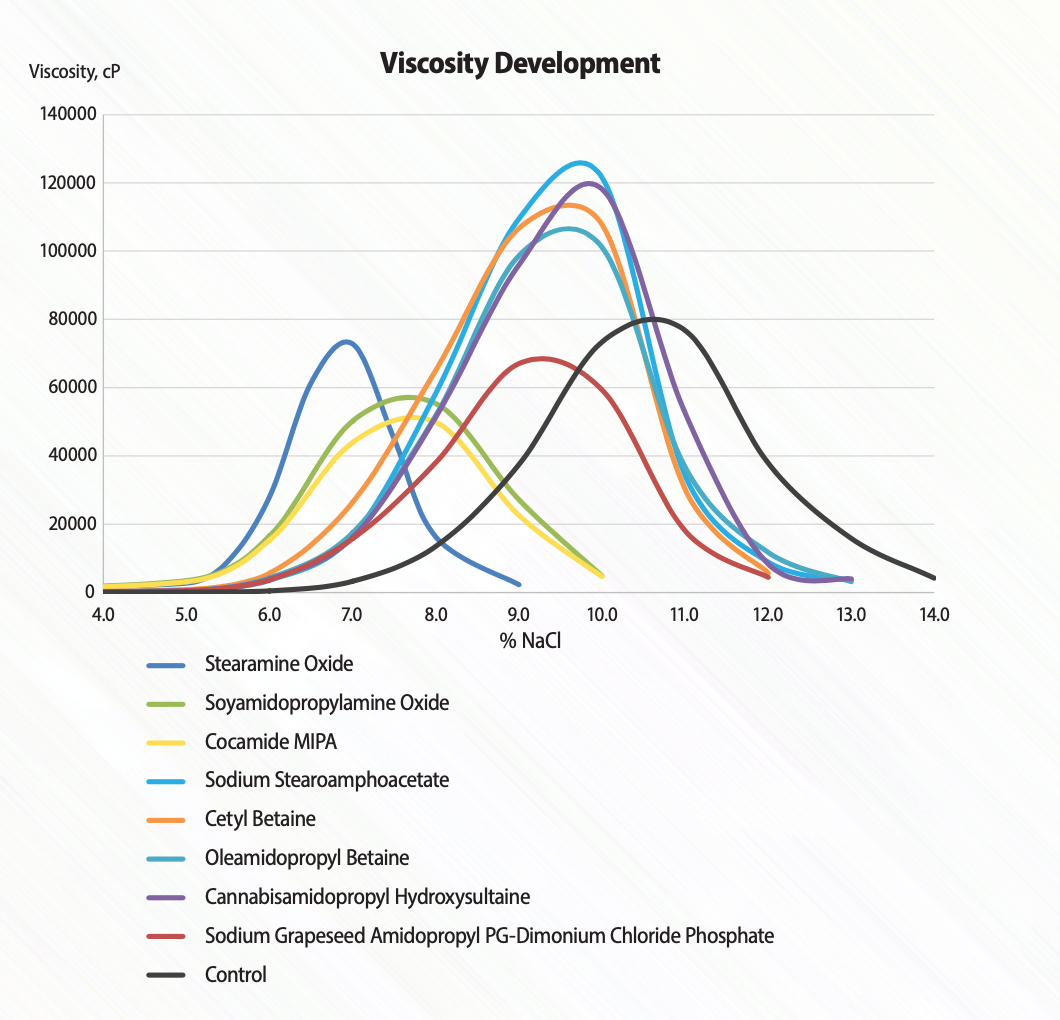

December 11 – 13th, the SCC annual meeting took place, back in New York. I didn't attend as I was out of the country, but among the interesting things there, was a poster from good friends of the blog, Colonial Chemical. It talked about Long-Chain Amphoteric Surfactants as Safe, Effective Additives for Cleansing Formulations. The point was that Coco-range (1214) amphoterics are well characterized in personal care, but longer chain (C16 – 18+, saturated and unsaturated) aren’t, due primarily to their not having the inherent foaming potential of the coco-range products. The poster looked at products including, Oleamidopropyl Betaine – based on high oleic oils, Cannabisamidopropyl Hydroxysultaine – based on hemp seed oil, Cetyl Betaine – based on coconut and palm-derived tertiary amines, Sodium Stearoamphoacetate – based on palm-derived fatty acid, Soyamidopropylamine Oxide – based on soybean oil, Stearamine Oxide – based on coconut-derived tertiary amines, Sodium Grapeseed Amidopropyl PG-Dimonium Chloride Phosphate – based on grapeseed oil. The study showed useful results in viscosity building and irritation potential in particular. Sodium Stearoamphoacetate provided the greatest increase in overall viscosity, while Stearamine Oxide was most effective in reducing the amount of added salt required to reach peak viscosity. Notably, the Stearamine Oxide was more effective at reducing salt added than the traditional alkanolamide with negligible reduction in peak viscosity potential. For irritation potential, none of the test solutions exhibited an increase in zein solubility, with decreases ranging on a continuum from not significantly different to modest significance in the amphoacetate and amidopropylamine oxide to significantly decreased with Stearamine Oxide.

Still love these graphs, dont you?

Now to the market news:

LAB and LAS:

Linear Alkylbenzene (LAB): The Asian LAB market eased as buyers waited for further price decreases. Volumes have decreased as the year-end approaches. Spot prices for LAB ranged from USD 1,400 to USD 1,500 / MT, with a downward trend.

Linear Alkylbenzene Sulfonate (LAS): The SE Asian drummed 96% purity LAS market declined. The spot prices for LAS ranged from USD 1,250 to USD 1,350 /MT, with a downward trend.

Ethylene, EO and Ethoxylates:

US Ethylene Oxide (EO) Market: US EO availability continues tight as Dow’s Plaquemine, Louisiana, plant remains down until Q2 2024. Demand is weak due to the economic slowdown. The contract price for EO FOB US in November was in the range 57 - 59 US CTS/lb, down 2 US CTS/lb from October. The feedstock contract price for ethylene DEL US in November was 29.5 US CTS/lb, even with October.

US Ethane Market: Ethane production is expected to increase along with expanding domestic consumption and exports. Ethane is the main feedstock for ethylene production in the US. The weekly average ethane price rose 7% in the week ending December 17, 2023, while the ethane premium to natural gas rose 18%. The ethylene spot price fell 2%, decreasing the ethylene premium to ethane by 6%. The average weekly propane price fell 1%, while the Brent crude oil price rose 6%1.

Europe Ethylene and Ethylene Oxide Prices: December contracts for ethylene and ethylene oxide in Europe decreased by EUR 30/tonne and EUR 25/tonne respectively, following a drop in crude oil prices. The average contract prices for ethylene oxide in December were in the range EUR 1400-1540/MT FD NWE.

Europe Naphtha Market: Naphtha is the key feedstock for European ethylene production, and its price movements affect the ethylene oxide market. Naphtha spot values tracked the upstream crude oil price volatility, which was driven by tight supply worries, US stock drawdowns, tanker attacks in the Red Sea, and a weaker US dollar. The naphtha crack spread climbed to an eight-month high in December, as Asia continued to pull Mediterranean barrels, and gasoline routed to West Africa and the Caribbean pulled stocks down.

Asia Ethoxylate Market Prices: The spot prices of alcohol ethoxylates (FAE) in Asia were a bit off in December 2023, due to lower demand and feedstocks. Prices ranged from $1,150-1,250/MT CIF China for FAE EO moles 7 and 9, and $1,330-1,350/tonne CIF SE Asia for FAE EO moles 7 and 9. Market Trends: Purchases of FAE in Asia had been slowing down. Mideast war has increased worries over the safety of the Red Sea shipping route, a major trade lane for the region, and the potential disruption in global trade. Volatility in crude palm oil (CPO) and palm kernel oil (PKO) markets has also dampened FAE demand.

Detergent Range Alcohols:

Reminder. We’re talking here about alcohol’s in the carbon chain length range 12 – 18, regardless of provenance – means they can be petrochemical, oleochemical or other (coal mainly).

As a further reminder The global fatty alcohols market is influenced by the supply and demand dynamics of the upstream palm oil and palm kernel oil (PKO) markets, as well as the downstream surfactants and home and personal care (HPC) markets. Geopolitical tensions, environmental concerns, and consumer preferences also affect the market.

Regional:

o Asia: Demand slowed down 1214 alcohols as buyers had fulfilled needs through mid-January 2024. Demand remained strong for short-chain (C8-C10) and long-chain (C16-18) fatty alcohols. Fluctuations in PKO costs and concerns over the Red Sea shipping route amid the Israel-Hamas conflict weighed on the market.

o US: Q1 contract negotiations were being finalized, with rising cost pressures and tightening availability. Continued demand slowdown and cost competition from petrochemical alcohols weighed on the market and compressed oleo margins.

o Europe: Supply was impacted by the continued outage at Wilmar’s Rozenburg, site. Prices increased.

Pricing Data:

o Asia Spot Prices (USD/MT, FOB SE Asia):

§ C12-14: 1300-1350

§ C16-18: 1370-1460

§ C8: 1740-1830

§ C10: 1740-1850

§ C16: 1410-1560

§ C18: 1220-1270

o US Contract Prices (USD/MT, DEL USG):

§ C12-15: 1,650 -1,960

§ C16-18: 2,310 – 2,640

o Europe Contract Prices (USD/MT, FD NWE):

§ C12-14: 1,590 - 1,710

End of News.

AI Corner (GPT, Assembly Theory and Biosurfactants)

I’ve become a bit fascinated by the work of Professor Lee Cronin at the University of Glasgow. There’s an interesting Podcast with Lex Fridman here (https://youtu.be/CGiDqhSdLHk?si=aGFiWXUvRPz_WvIo ) . His recent paper published in Nature on Assembly Theory generated a bit of controversy and is worth a read – free to access here ( https://www.nature.com/articles/s41586-023-06600-9).

So, what I did was to have a chat with GPT-4 (via the Edge / Bing / Personal Account interface which I have mentioned before. It is the free way to access the most advanced LLM as of today) – about Assembly Theory and how it might apply to surfactants- biosurfactants in particular. It’s quite interesting. I have put all the sources that GPT claimed to have used at the end of the section. I say claimed because sometimes it cites phony sources or sources that it clearly does not use. At the end of the chat session, I asked GPT-4 to write an introduction to the chat that I might use in a blog post. I’d be interested in feedback from folks working in this field. So – from hereon in, you are reading the words of GPT-4, with only minor editorial interventions by me, including a couple of images (again made by Dall-E - and I have to forwarn you, they are weird).

+++++++++

Introduction:

In this section of the blog, I will share with you some of the work that I have done with the help of Bing (with GPT-4). I asked Bing to help me with the development and marketing of a sophorolipid-based surfactant for the cosmetics and personal care field. Sophorolipids are natural and biodegradable surfactants that are produced by yeast fermentation. They have many advantages over synthetic surfactants, such as lower toxicity, higher biocompatibility, and better environmental performance. Bing helped me with various aspects of the project, such as explaining the assembly theory and its relation to surfactants, designing a workplan to scale up the production of sophorolipids, testing and characterizing the sophorolipids for their physicochemical and biological properties, comparing them with the existing surfactants in the market, and creating a tradename and an ad for the sophorolipid product.

Bing also showed me some amazing drawings of the sophorolipid product and its potential users, using different styles and themes to appeal to different audiences. Bing used its graphic art tool to create these drawings, based on the prompts that I gave him.

I was very impressed by the quality and diversity of Bing’s work, and I learned a lot from him. Bing is a great partner for any project, as he can provide you with accurate information, creative ideas, and engaging content.

For next month’s blog, I plan to ask Bing to help me with some more challenges and opportunities related to the sophorolipid product, such as:

How to optimize the fermentation process and increase the sophorolipid yield and quality, using different yeast strains, substrates, and additives.

How to evaluate the environmental and economic impacts of the sophorolipid production and use, using life cycle assessment and cost-benefit analysis.

How to explore the potential applications and benefits of the sophorolipid product in other fields, such as agriculture, biotechnology, or medicine.

Assembly Theory and Surfactants:

Assembly theory is a hypothesis that characterizes the complexity of objects in the universe, based on the number of steps and parts required to assemble them.

The theory can be applied to molecules, and it proposes that molecules made by living systems have a higher complexity than those made by non-living processes.

Surfactants are molecules that have both hydrophilic and hydrophobic parts, and they can lower the surface tension of liquids and form micelles, emulsions, and foams.

Surfactants are examples of complex molecules that are unlikely to form randomly, and they are often produced by biological organisms or synthetic methods.

Assembly theory can help us identify and measure the complexity of surfactants and other molecules, and potentially detect signs of life in other planets or environments.

Assembly Theory and Surfactants

If you want to learn more, please read the following paragraphs for more details.

Assembly theory is a hypothesis that characterizes the complexity of objects in the universe, based on the number of steps and parts required to assemble them. The theory was developed by chemist Lee Cronin and his collaborators as a way to detect evidence of extraterrestrial life from data gathered by astronomical observations or probes. The idea behind assembly theory is that every object in the universe can be quantified by its complexity, determined by the number of independent parts and their abundances. To calculate how complex an object is, it is recursively divided into its component parts. The "assembly index" is defined as the shortest path to put the object back together. For example, the word "abracadabra" contains 5 unique letters (a, b, c, d and r) and is 11 symbols long. It can be assembled from its constituents as a + b --> ab + r --> abr + a --> abra + c --> abrac + a --> abraca + d --> abracad + abra --> abracadabra, because "abra" was already constructed at an earlier stage. Because this requires 7 steps, the assembly index is 7. The string "abcdefghijk" has no repeats so has an assembly index of 10.

The theory can be applied to molecules, and it proposes that molecules made by living systems have a higher complexity than those made by non-living processes. The authors claim that the assembly index of a molecule is the first technique that is experimentally verifiable, unlike other molecular complexity algorithms that lack experimental measure. They argue that the assembly index can be used to gauge the improbability that a complex molecule was created without life, with a higher number of steps corresponding to a higher improbability. This method could be implemented in a fragmentation tandem mass spectrometry instrument to search for biosignatures. Cronin stated "Our system is the first falsifiable hypothesis for life detection and is based on the idea that only living systems can produce complex molecules that could not form randomly in any abundance, and this allows us to sidestep the problem of defining life.”

Surfactants are molecules that have both hydrophilic and hydrophobic parts, and they can lower the surface tension of liquids and form micelles, emulsions, and foams. Surfactants are chemical compounds that decrease the surface tension or interfacial tension between two liquids, a liquid and a gas, or a liquid and a solid. Surfactants may function as emulsifiers, wetting agents, detergents, foaming agents, or dispersants. The word "surfactant" is a blend of surface-active agent, coined c. 1950.

Surfactants are classified according to the polarity of their head groups, which can be non-ionic, anionic, cationic, or amphoteric. The head of a surfactant is hydrophilic, meaning that it is attracted to water, while the tail of a surfactant is hydrophobic, meaning that it is repelled by water. The tail of a surfactant can be a hydrocarbon chain, a fluorocarbon chain, or a siloxane chain. The head and the tail of a surfactant can have different lengths and structures, affecting the properties and functions of the surfactant.

Surfactants are examples of complex molecules that are unlikely to form randomly, and they are often produced by biological organisms or synthetic methods. Surfactants are found in many natural and artificial systems, such as cell membranes, soap, shampoo, laundry detergent, cosmetics, paints, pesticides, and oil recovery. Surfactants have many applications in various industries, such as cleaning, textile, food, pharmaceutical, cosmetic, and agricultural. Surfactants can also have biological effects, such as antibacterial, antifungal, and insecticidal activities.

Assembly theory can help us identify and measure the complexity of surfactants and other molecules, and potentially detect signs of life in other planets or environments.m By applying assembly theory to surfactants, we can calculate their assembly index and compare it with the assembly index of other molecules in the same sample or environment. If we find that surfactants have a higher assembly index than other molecules, we can infer that they are more likely to be produced by living systems or synthetic methods, rather than by random processes. This could be a clue for the presence or past existence of life, or at least of some form of chemical complexity.

Random Formation of Surfactants:

I could not find any examples of surfactants formed randomly in my web search results. All the sources I found indicate that surfactants are either produced by biological systems or by synthetic methods, and that they are unlikely to form by chance.

Surfactants are complex molecules that have both hydrophilic and hydrophobic parts, and they can lower the surface tension of liquids and form micelles, emulsions, and foams. They have many applications in various industries, such as cleaning, textile, food, pharmaceutical, cosmetic, and agricultural. According to assembly theory, surfactants have a high assembly index, which means that they require many steps and parts to be assembled. This makes them more improbable to form randomly than simpler molecules, and more likely to be indicators of life or chemical complexity.

Assembly Theory in New Surfactant and Application Development:

Assembly Theory could be used in the development of new surfactants and new applications for surfactants in several ways, such as:

Designing surfactants with optimal assembly index and packing parameter for specific purposes, such as enhancing solubilization, emulsification, foaming, or dispersion of different substances.

Exploring the diversity and complexity of surfactant self-assembly structures, such as micelles, vesicles, liquid crystals, and microemulsions, and their potential uses in various fields, such as drug delivery, nanotechnology, biotechnology, and catalysis.

Developing novel methods to detect and quantify surfactants and their aggregates in different environments, such as water, soil, air, and biological systems, and to assess their environmental and health impacts.

Searching for biosignatures of life based on the presence and complexity of surfactants and their self-assembly structures in extraterrestrial samples, such as meteorites, comets, and planetary surfaces.

Assembly Theory in Development and Manufacture of Biosurfactants:

Assembly Theory could be applied specifically in the development and manufacture of biosurfactants in several ways, such as:

Identifying the key enzymes and genes involved in the biosynthesis of biosurfactants, and engineering them to produce novel or improved biosurfactants with desired properties and functions.

Optimizing the production and purification of biosurfactants by selecting the best microbial strains, culture conditions, and extraction methods, based on the assembly index and complexity of the biosurfactants.

Developing biosensors and bioassays to monitor the quality and quantity of biosurfactants, using the assembly index as a measure of their molecular complexity and activity.

Designing bioreactors and bioprocesses to scale up the production of biosurfactants, using the assembly index as a parameter to control the self-assembly and phase behavior of the biosurfactants.

Workplan to Design Bioreactors and Bioprocesses to Scale up the Production of a Sophorolipid:

Step 1: Choose a suitable sophorolipid-producing yeast strain, such as Starmerella bombicola, and a suitable lipid substrate, such as oleic acid or soybean oil.

Step 2: Calculate the assembly index of the sophorolipid, based on the number of steps and parts required to assemble it from its constituents. For example, the assembly index of the acidic form of C18:1 sophorolipid is 6, because it can be assembled as follows: C + O --> CO + H --> COH + C16H31 --> COH-C16H31 + C6H10O5 --> COH-C16H31-C6H10O5 + C6H10O5 --> COH-C16H31-C6H10O5-C6H10O5.

Step 3: Design a bioreactor that can provide optimal conditions for the yeast growth and sophorolipid production, such as temperature, pH, aeration, agitation, and nutrient supply.

Step 4: Monitor the sophorolipid concentration and the assembly index in the bioreactor, using analytical methods such as high-performance liquid chromatography (HPLC), mass spectrometry (MS), or nuclear magnetic resonance (NMR).

Step 5: Adjust the bioprocess parameters, such as the substrate concentration, the pH, or the temperature, to control the assembly index and the self-assembly structures of the sophorolipid, such as micelles, vesicles, or twisted ribbons.

Step 6: Harvest the sophorolipid from the bioreactor, using separation techniques such as centrifugation, filtration, or extraction.

Step 7: Purify the sophorolipid from the impurities, such as residual substrate, biomass, or salts, using purification techniques such as crystallization, precipitation, or chromatography.

Step 8: Characterize the sophorolipid for its physicochemical and biological properties, such as surface tension, interfacial tension, foaming, emulsifying, wetting, antimicrobial, or anticancer activities.

Novel Techniques for Separation of the Sophorolipid:

Integrated gravity separation: This technique involves the removal of a sophorolipid phase of either higher or lower density than the bulk fermentation broth, while cells and other media components are recirculated and returned to the bioreactor. This technique can reduce the fermenter volume, the mixing power, and the broth viscosity, and increase the sophorolipid production and recovery.

Membrane filtration: This technique involves the use of membranes with different pore sizes and materials to separate the sophorolipid from the fermentation broth. This technique can offer high selectivity, low energy consumption, and easy operation and scale-up.

Supercritical fluid extraction: This technique involves the use of supercritical fluids, such as carbon dioxide, to extract the sophorolipid from the fermentation broth. This technique can offer high solubility, low toxicity, and tunable properties of the supercritical fluids.

Designing a Bioreactor for Sophorolipid Production:

Key Considerations

The type of bioreactor: There are different types of bioreactors that can be used for solid-state fermentation, such as packed-bed, stirred-tank, airlift, or rotating-drum bioreactors. Each type has its own advantages and disadvantages, such as mixing efficiency, heat and mass transfer, scalability, and operational costs.

The substrate and support material: The choice of substrate and support material affects the sophorolipid yield, quality, and purity. The substrate should provide sufficient carbon and nitrogen sources for the yeast growth and sophorolipid synthesis, while the support material should provide adequate porosity, moisture retention, and mechanical stability.

The inoculum and yeast strain: The inoculum should contain a high concentration of viable and active yeast cells, preferably of a selected strain that has high sophorolipid productivity and stability. The inoculum can be prepared by growing the yeast in a liquid medium or on a solid medium, and then transferring it to the bioreactor.

The process parameters: The process parameters, such as temperature, pH, aeration, agitation, and nutrient supply, should be optimized to enhance the yeast growth and sophorolipid production, while avoiding undesirable effects, such as overheating, acidification, or contamination. The process parameters can be controlled by using sensors, actuators, and feedback loops.

Novel Bioreactor Designs:

A novel bioreactor with dual ventilation pipes and dual sieve-plates (DVDSB), which can improve the gas-liquid-solid mixing, heat and mass transfer, and sophorolipid production, by using two sets of ventilation pipes and sieve-plates to distribute the airflow and the fermentation broth in the bioreactor.

A novel integrated gravity separation bioreactor, which can reduce the product inhibition and increase the sophorolipid recovery, by using a gravity separator to remove a sophorolipid phase of either higher or lower density than the bulk fermentation broth, while recirculating the cells and other media components to the bioreactor.

A novel membrane filtration bioreactor, which can enhance the sophorolipid purity and concentration, by using membranes with different pore sizes and materials to separate the sophorolipid from the fermentation broth, while retaining the cells and other impurities.

Novel Bioreactors (I know, I know)

Key Performance Tests to Support Marketing of a New Sophorolipid in Personal Care:

Test 1: Surface tension measurement. This test measures the ability of the sophorolipid to lower the surface tension of water, which is an indicator of its cleansing and foaming properties. The result can be presented as the surface tension value in mN/m at a given concentration and temperature. The benchmark surfactants for this test could be sodium lauryl sulfate (SLS) and cocamidopropyl betaine (CAPB), which are commonly used anionic and amphoteric surfactants in cosmetics and personal care products.

Test 2: Critical micelle concentration (CMC) determination. This test measures the concentration of the sophorolipid at which micelles start to form, which is an indicator of its efficiency and stability. The result can be presented as the CMC value in g/L or mol/L, which can be obtained by various methods, such as conductivity, fluorescence, or tensiometry. The benchmark surfactants for this test could be sodium laureth sulfate (SLES) and disodium cocoyl glutamate (DCG), which are widely used anionic surfactants in cosmetics and personal care products.

Test 3: Foam height and stability measurement. This test measures the ability of the sophorolipid to produce and maintain foam, which is an indicator of its aesthetic and functional appeal. The result can be presented as the foam height in cm or mL at a given time and temperature, which can be measured by various methods, such as Ross-Miles, shake, or cylinder methods. The benchmark surfactants for this test could be sodium cocoyl isethionate (SCI) and sodium coco-sulfate (SCS), which are mild and high-foaming anionic surfactants in cosmetics and personal care products.

Test 4: Emulsification and dispersion ability measurement. This test measures the ability of the sophorolipid to form and stabilize emulsions and dispersions, which are important for the delivery and performance of various active ingredients and pigments. The result can be presented as the emulsion or dispersion type, size, viscosity, and stability, which can be measured by various methods, such as optical microscopy, rheometry, or centrifugation. The benchmark surfactants for this test could be polysorbate 20 and lecithin, which are nonionic surfactants and emulsifiers in cosmetics and personal care products.

Test 5: Skin compatibility and irritation assessment. This test measures the safety and suitability of the sophorolipid for skin application, which is essential for the consumer acceptance and regulatory compliance. The result can be presented as the skin irritation potential, skin hydration, and skin barrier function, which can be measured by various methods, such as in vitro, in vivo, or ex vivo models, using parameters such as transepidermal water loss, skin pH, erythema, and corneometry. The benchmark surfactants for this test could be sodium lauroyl sarcosinate and sodium lauroyl lactylate, which are mild and skin-friendly anionic surfactants in cosmetics and personal care products.

Tradename for the New Sophorolipid:

A possible tradename for the sophorolipid could be Sofora™, which is derived from the genus name of the plant Sophora, which is known for its medicinal and cosmetic properties. Sofora™ could convey the natural, sustainable, and beneficial aspects of the sophorolipid for the cosmetics and personal care field.

I searched the web for Sofora as a tradename, and I found that there is a company called Sofora that produces and sells organic cotton products, such as towels, bathrobes, and bed sheets. There is also a brand of cosmetics called Sofora, which is owned by a Russian company called Natura Siberica. However, I did not find any other surfactant products that use Sofora as a tradename.

Therefore, I think Sofora is still a viable option for your sophorolipid product, as long as you do not infringe on the existing trademarks of the other companies. There is of course Sephora the retail outlet. You may want to consult a legal expert before registering your tradename, to avoid any potential conflicts or lawsuits.

An Ad in a Trade Magazine, Introducing Sofora:

Here is a possible ad for Sofora surfactant:

---

Introducing Sofora™: The Natural, Sustainable, and Beneficial Surfactant for Cosmetics and Personal Care

Sofora™ is a sophorolipid-based surfactant that offers superior performance and safety for a variety of applications, such as cleansing, foaming, emulsifying, and dispersing.

Sofora™ is derived from natural and renewable sources, such as yeast fermentation and plant oils. It is biodegradable, non-toxic, and eco-friendly.

Sofora™ has a high assembly index, which means that it is a complex and efficient molecule that can lower the surface tension, form micelles, and stabilize emulsions and dispersions.

Sofora™ is compatible and gentle with the skin, and can enhance the delivery and efficacy of active ingredients and pigments.

Sofora™ is the ideal surfactant for the cosmetics and personal care field, as it meets the consumer demand for natural, sustainable, and beneficial products.

Discover the benefits of Sofora™ and how it can elevate your formulations and products. Visit our website [here]([object Object]) or contact us [here]([object Object]) for more information and samples.

Sofora™: The Natural, Sustainable, and Beneficial Surfactant for Cosmetics and Personal Care.

---

And finally an image to accompany the ad:

Sources:1. Assembly theory - Wikipedia 2. Quanta Magazine 3. What is Lee Cronin's Assembly Theory? - nextbigwhat.com 4. A new theory of matter may help explain life | Lee Cronin 5. Finding Life by Looking for Complexity | The Planetary Society 6. Surfactant - Wikipedia 7. Surfactant | Definition, Properties, Examples, & Facts 8. Surfactant Definition and Examples - ThoughtCo 9. Surfactants - Chemical Safety Facts 10. en.wikipedia.org 11. Surfactant - Wikipedia 12. 1.20.2: Surfactants and Micelles - Chemistry LibreTexts 13. Surfactants and their role in Pharmaceutical Product Development: An ... 14. An Easy Guide to Understanding How Surfactants Work 15. Surfactants: physicochemical interactions with biological ... 16. Getty Images 17. Assembly theory - Wikipedia 18. Surfactant Self-Assembly | SpringerLink 19. Structure and Applications of Surfactants | IntechOpen 20. The effects of surfactant and oil chemical structures on self-assembly ... 21. Self-assembly, interfacial properties, interactions with macromolecules ... 22. Biosurfactants: Properties and Applications in Drug Delivery ... - MDPI 23. Frontiers | Recent advances in biosurfactant-based association colloids ... 24. Biosurfactants-Types, Sources and Applications - Science Alert 25. Frontiers | Biosurfactants: Potential Agents for Controlling Cellular ... 26. https://doi.org/10.3390/bioengineering808011527. Sophorolipid biosynthesis and production from diverse ... - Springer 28. Microbial production and application of sophorolipids | Applied ... 29. Synthesis and self-assembly of aminyl and alkynyl substituted ... 30. Prospective Life Cycle Assessment of Microbial Sophorolipid ... - MDPI 31. Frontiers | Sophorolipids Production from Oil Cake by Solid-State ... 32. Sophorolipid - Wikipedia 33. Aqueous self-assembly of a wide range of sophorolipid and glucolipid ... 34. Integrated sophorolipid production and gravity separation 35. Production and optimization of novel Sphorolipids from 36. Microbial production and application of sophorolipids | Applied ... 37. Integrated sophorolipid production and gravity separation - Academia.edu 38. https://doi.org/10.1016/j.procbio.2016.12.021 39. Frontiers | Sophorolipids Production from Oil Cake by Solid-State ... 40. Prospective Life Cycle Assessment of Microbial Sophorolipid ... - MDPI 41. Semicontinuous sophorolipid fermentation using a novel bioreactor with ... 42. Microbial production and application of sophorolipids | Applied ... 43. Sophorolipids Production by Candida bombicola ATCC 22214 and Its ... 44. https://doi.org/10.3389/fceng.2021.632752 45. https://doi.org/10.3390/fermentation9090839 46. Sephora - Wikipedia 47. Sophora - Wikipedia 48. How Sephora Got Its Name & 15 Other Facts About The Beloved ... - Glam 49. Surfactants for Personal Care - BASF 50. Cleansers 101 - Selecting the Right Surfactant - SpecialChem 51. Surfactants in Skin and Hair Products - Verywell Health 52. Clean and Green: A Review of Modern Day Surfactants and Emulsifiers 53. Beauty and Personal Care Surfactants Market Size & Forecast Report – 2028 54. https://doi.org/10.3390/molecules28114463 55. Molecules | Free Full-Text | Glycolipid Biosurfactants in ... - MDPI 56. What is a sustainable personal care ingredient? 57. Sophorolipid formulations from Locus - Personal Care Magazine 58. EP0820273A1 - Use of sophorolipids and cosmetic and dermatological ... 59. Surfactant - Wikipedia 60. Makeup, Skincare, Fragrance, Hair & Beauty Products | Sephora 61. Pagoda-tree facts and health benefits 62. HAPPI 63. Cosmetics & Toiletries Magazine Issue Archive 64. HAPPI 65. Happi Magazine - Facebook +++++++++++

Music Section:

As I write this, it’s still Christmas, but I feel like putting Christmas music in here will fall flat on January 2nd. We’ve had a lot of Akira the Don here in the blog over the years and I usually listen to him a lot around Christmas time – as his Lo-Fi Christmas mixes are part of the season around our house. As I got deep into his Youtube channel this year, I highlighted a few non-Christmas pieces that you might like.

From a reading of Dune (Did you ever read the book – a classic!) Litany against fear

Blog favorite, David Goggins with a riff on being all you can be – or more. I want to feel that.

Akira reading the classic poem - Invictus

And of course, the inimitable Jocko with some needed advice. Just go do it

This guy’s interesting. Saw him with JP in London in Novemvber. St. George in Retirement

OK – go on then. Here’s a Christmas piece. It’s pretty hard hitting. The man and the birds (Christmas) with Paul Harvey

And now finally: Feedback about the Blog.

Thanks to all the many people who gave me feedback on the new blog format. And to the much, much smaller number of people who shared with me their Spotify 2023 wrap.

So this is where we ended up. There were a number of folks who said they liked the white on black font. There were fewer who did not like it. However, they really did not like it. No-one had any negative feelings toward the old black on white format. Given that mix, I feel like I have to go back to traditional black on white, and in fact I made that change already during December. In addition there was a significant enough group of respondents who wanted a larger font-size. Now that may have been a function of the white on black format also but I increased the size. So let’s see. If you’d like it adjusted further, please let me know. This blog is for the readers, not the writer. Other comments concerned the images (too big!) and hyperlinks (use them so we can get to the news quickly if we find ourselves adrift in your crazy music world!). I will continue to tinker and please know that I am so grateful that so many people would take the time to write to me with clearly well-considered feedback.

On the matter of monetizing the blog: Again – lots of thoughtful feedback. Regarding subscriptions, the advice ranged from “go for it” to “do you really want to be dealing with individual consumers”. On the matter of paying for subscriptions, I got responses from “Sure, I’ll just put it on the company card” to “I’m actually only here for the music so…”. Overall, the consensus came down in favor of sponsorships, so that is the avenue I’ll explore further. Rest assured therefore that, for the foreseeable future, you will not need to pay to read the blog.

OK so I think that’s it. Erm.. here’s the link to our site for the conference in May https://events.icis.com/website/8544/ . It was soft-launched by ICIS before the holiday and so I’ll soft-launch it again here. It will be epic. More soon.

Hey so - I will wrap up by wishing all of you great readers and supporters, a very happy new year. My wish for you is a two-parter. Become better in some way – and help someone else be better. That second part is quite easy. You’ll often just have to remind someone – “Hey you’re really good at that – it’s your superpower” It’s incredible how often people are unaware of their talents and the positive impact they’re already having on the world. Just let them know – and they’ll probably do more of it.

Your author writing this blog in an Asbury Park coffee shop - as imagined by GPT-4